Dimension Tolerance Calculator

Dimension Tolerance Calculator - Web maximum material condition (mmc) is a gd&t symbol indicating the maximum or minimum allowed tolerance of a feature where it has the maximum amount of material. Tolerance calculator fill the required inputs and click check. It is not possible to define. Web fits and tolerances calculator calculate fits and tolerances for shafts and holes here. Limits of sizes that calculated are the extreme values, within which the actual size of the dimension.

Web table of metric hole tolerances per. Tolerance is the total allowable variance in a dimension, i.e., the difference between the upper and lower. Web fits and tolerances calculator calculate fits and tolerances for shafts and holes here. All internal calculations are done in metric. Web our online fit calculator not only calculates the maximum tolerated dimensions for a given nominal dimension and type of fit, but as the first fit calculator, also does the reverse. Web iso tolerance calculator description the calculations are based on the british standard metric iso limits and fits. Web fits and tolerances calculator.

Metric Tolerance Chart for ISO 2862 Round Bar Tolerances

Based on standard tolerances and limit deviations in accordance with iso 286. The schematic representation of the fit is also drawn by tolerance calculator. Web the following engineering calculator will show the plus and minus.

MECHANICAL TOLERANCE EASY WAY TO CALCULATE TOLERANCE USING EXCEL

Find your data faster with our fits and tolerance. Calculate fits and tolerances for shafts and holes here. Tolerance calculator fill the required inputs and click check. Web fits and tolerances calculator calculate fits and.

International Tolerance (IT) Grades Table Chart Engineers Edge

Tolerance calculator fill the required inputs and click check. Calculate fits and tolerances for shafts and holes here. Web fits and tolerances calculator calculate fits and tolerances for shafts and holes here. Web the following.

General Tolerances for Linear and Angular Dimensions ISO 2768

Web iso tolerance calculator description the calculations are based on the british standard metric iso limits and fits. Green = prefered tolerance classes. Tolerance calculator fill the required inputs and click check. Ansi limits and.

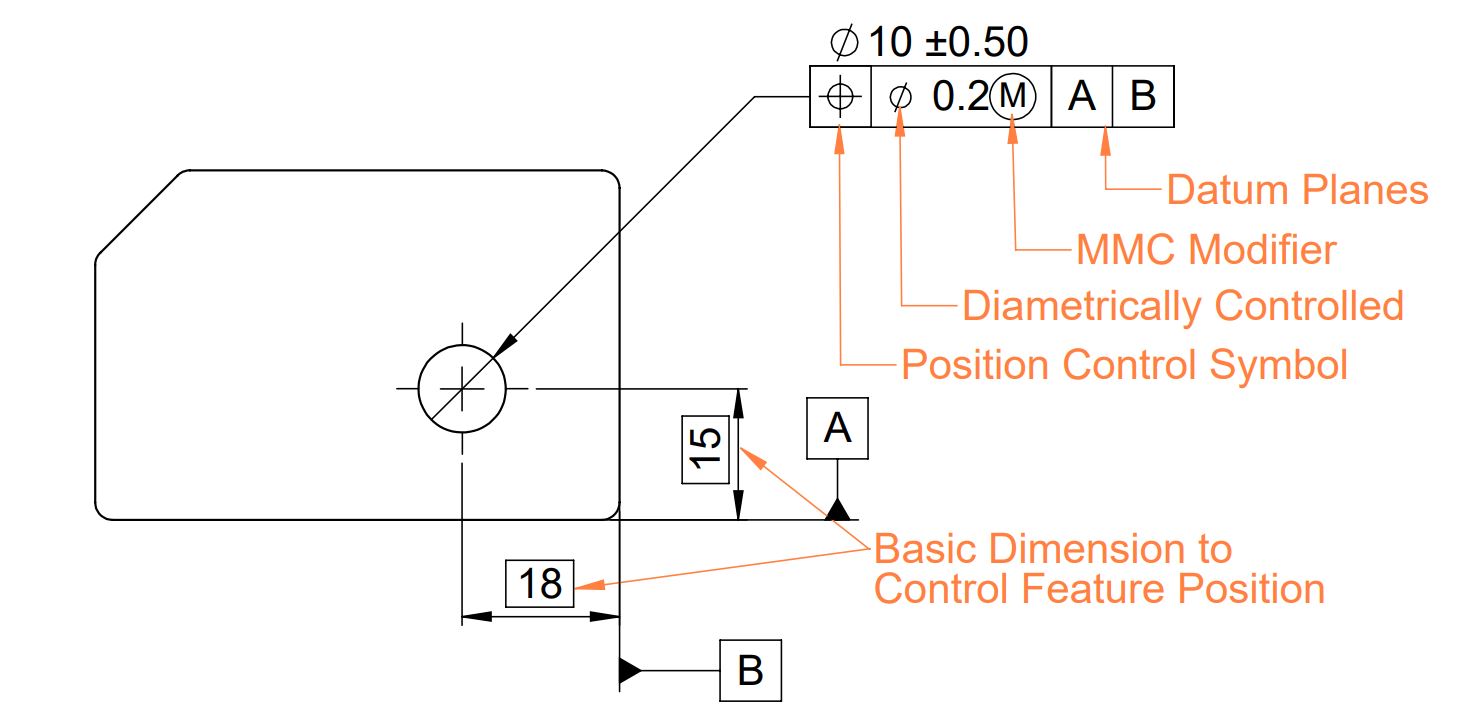

Position Control Tolerance Geometric Dimension and Control

Web tolerance analysis calculator a free shareable tool for worst case and root sum squared tolerance analysis for mechanical design. Tolerance is the total allowable variance in a dimension, i.e., the difference between the upper.

GD&T Basics Introduction to Geometric Dimension and Tolerance (2023)

Green = prefered tolerance classes. How to use this calculator? Ansi limits and fits calculator. Web ansi b4.1 preferred limits and fits for cylindrical parts. Calculate fits and tolerances for shafts and holes here.

Geometric Tolerance Chart

Calculate fits and tolerances for shafts and holes here. Web our online fit calculator not only calculates the maximum tolerated dimensions for a given nominal dimension and type of fit, but as the first fit.

Position Control Tolerance Geometric Dimension and Control

Ansi preferred tolerances and fits charts. Tolerance is the total allowable variance in a dimension, i.e., the difference between the upper and lower. Limits of sizes that calculated are the extreme values, within which the.

How to calculate mmc for hole position tolerance calculator coutureper

Web the difference between 0.498 and 0.497, or 0.001, is the allowance. Calculate fits and tolerances for shafts and holes here. Web tolerance analysis calculator a free shareable tool for worst case and root sum.

Dimensional tolerances WS STAHL

Web table of metric hole tolerances per. Web tolerance calculator calculate the tolerances of shafts and holes based on iso 2768. Web iso 286 table hole tolerances calculator international tolerance grades variations on dimensions without.

Dimension Tolerance Calculator Web table of metric hole tolerances per. Web iso tolerance calculator description the calculations are based on the british standard metric iso limits and fits. Calculate fits and tolerances for shafts and holes here. Web maximum material condition (mmc) is a gd&t symbol indicating the maximum or minimum allowed tolerance of a feature where it has the maximum amount of material. How to use this calculator?